Developed and improved for over 40 years, the motorised drive rollers or MDR are the core component of advanced automated conveyor systems, it is now widely used and praised by a variety of industries and innovative logistic centers around the world.

MDR are used in the design of high capacity, cost efficient, flexible, reliable and safe installations.

Our extensive range of MDR and customisation options, can efficiently drive most types of conveyor applications, for light, medium or heavy loads transportation. It allows flawless automated material flows, all along the intralogistic processes (reception, storage, order preparation, shipping, assembly…)

The MDR are controlled either by internal circuit boards, or with external controllers, which range from standard control features (speed, direction, ...), to ZPA integrated logic, up to intelligent programmable IoT networked controllers.

Flexible and modular

- Easy integration within the conveyor

- Customised sizes

Cost efficient

- Almost maintenance free

- Extended product life

- Low power consumption

Safe

- Low voltage

- Stoppable by hand

- Quiet operation

Intelligent

- Integrated control logics (ZPA, slug, train …)

- Configurable speed, direction…

- Network communication (IoT)

- Predictive maintenance

Green

- Limited energy consumption

- Clean and recyclable

Products

Series PM 500-FE

It's designed for conveying light and medium loads for order preparation, distribution an dfor assembly lines. The circuit board is separated from the gear motor in order to optimize the performance, durability of the roller and to offer diverse functions such as pulse signals, acceleration/deceleration, optional position holder. The assembly can be controlled by PLC.

ELEKTROMECANICAL

Direct current and brushless

24V DC (+/- 10 %) - ripple ratio < 10 %

Insulation index

E

Operation at 40°C

Continuous: 100%

Intermittent:

1800 starts / hour maxi

Minimum duty cycle = 1 s ON/ 1 s OFF

ED = ON / (ON + OFF) ≤ 50 %

Brakes

Dynamic braking

Protection index

IP54 (IP65 or cold room, on request)

Cable length

300 mm with JST connector - 9 pins

Protection

Thermal protection (>95°C for circuit board, >110°C for motor)

Protection against induced voltage

Environment

0°C/+40°C - no condensation - or corrosive or explosive atmosphere

Vibrations < 0,5G

Sound level

≈ 52 dB nominal 1 meter away

Speed code

15 25 55 90

Reduction ratio

1/44,90 1/26,67 1/12,64 1/7,5

Connector

9-pin JST #S9B-XH-A

CONTROL

Circuit board functions

see characteristics of CBM-105 and HB 510

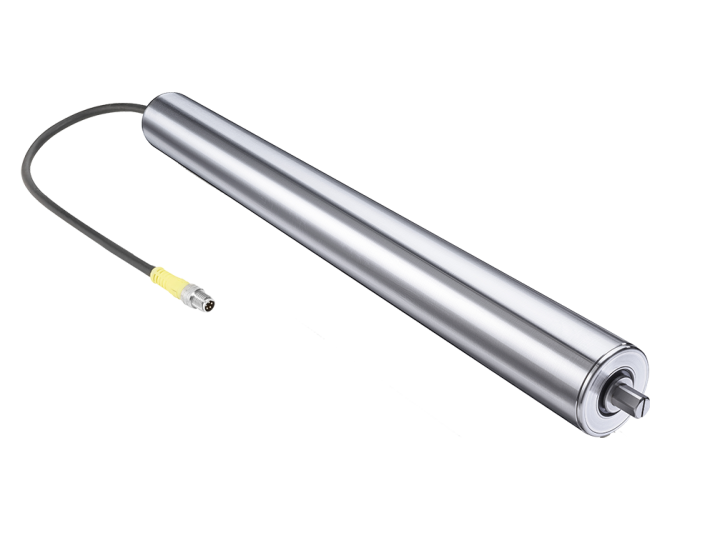

Series PM 500-VE

ELEKTROMECANICAL

Direct current and brushless

24 VDC (+/- 10 %) - ripple ratio < 10 %

Insulation class

E

Operation at 40°C

Intermittent: max. 1800 starts / hour maxi

Minimum duty cycle = 1 s ON / 1 s OFF

ED = ON / (ON+OFF) ≤ 50 %

Brake

Dynamic braking

Cable length and type

300 mm with M8-5P connector

Protection Index

IP54 (IP65 or cold room, on request)

Protection

Thermal protection (>95°C for circuit board, > 110°C for motor)

Protection against induced voltage

Environment

0°C/+40°C - no condensation - or corrosive or explosive atmosphere - Vibrations < 0,5 G

Sound lvel

≈ 52 dB nominal 1 meter away

Speed code

17 25 60 90

Reducion ratio

1/44,97 1/26,67 1/12,65 1/7,5

CONTROL

Circuit board functions

see characteristics of CBV-108, HBV-609 and IB-P

Series PM 500-XC

It's designed for conveying lines with light and medium loads (up to max. 300 kg) and is suitable for working environments such as those exposed to liquids and dust.

ELECTROMECANICAL

Direct current and brushless 24 VDC

24 VDC (+/- 10 %) - ripple ratio < 10 %

Insulation class

E

Operation at 40°C

Continuous: 100%

Intermittent: 1440 starts / hour maxi

Minimum duty cycle = 1s ON / 1s OFF

ED = ON / (ON + OFF) ≤ 40 %

Brakes

Servo-brake

Protection index

IP54

Cable length

500 mm with M8 connector - 5 pins snap-in type

Protection

Against overload by integrated thermistor

Against polarity reversal 0 - 24 VDC

Current limitation within circuit board

Integrated fuse 8A

Thermal protection (> 95°C for circuit board)

Protection against under supply (over 1s under 15 VDC)

Protection against induced voltage (> 40 VDC over 2s)

Protection against motor lock (> 0.5s)

Environment

0°C / + 40°C - no condensation - or corrosive or explosive atmosphere

Vibrations < 0,5 G

Sound level

≈ 54 dB nominal 1 meter away

Speed code

17 30 60 90

Reduction ratio

1/44,90 1/26,67 1/12,64 1/7,5

Start / Stop

Start: ≥ 2.0 VDC impedance ≥ 35kΩ

Stop (servo-brake): 0 ~ 1.9 VDC / Start

Speed variation

By external voltage,10 speeds, impedance ≥ 35kΩ

Error signal

NPN open collector, thermal, low voltage, back EMF.

Error signal is discharged when motor is locked condition for approx. 6s. Error signal is discharged when there is a speed deviation of +/- 20% from set speed for 10s.