We are a conveyor roller manufacturer!

|

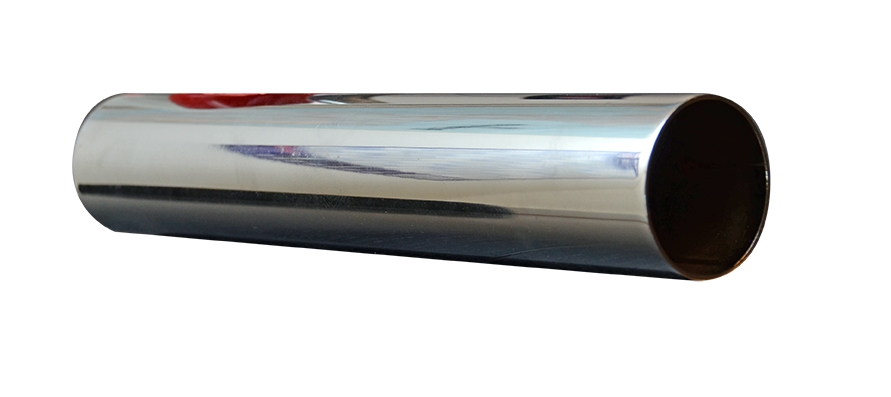

Improvement of surface quality and corrosion protection

Prevents marking of wooden conveyor rollers. Application in sawmills and timber mills.

Serves as corrosion protection and to improve the sliding properties of the axle material.

Different layer thicknesses and surface hardnesses go gentle on the material to be conveyed and reduce noise.

Different properties can be achieved depending on the coating method.

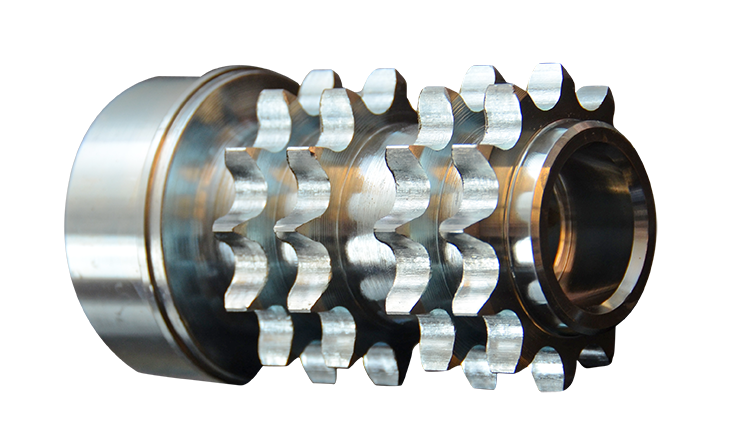

Greater wear-resistance is achieved through hardened tooth flanks.

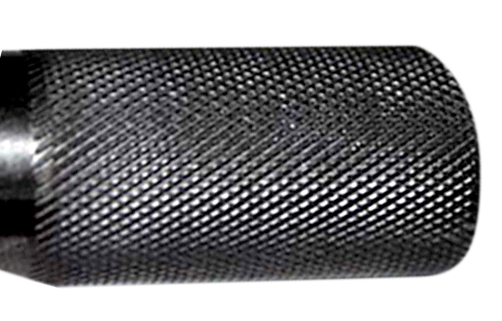

The knurling achieves improved overdrive to the material to be conveyed.

Cambering prevents the material to be conveyed from running off course both on the drive and output side.

We produce special chain wheels at customer request.

We product special flange rings at customer request.