Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) have long since become central components of modern intralogistics.

In smart factory and smart warehouse environments, these mobile robots and autonomous vehicles ensure a significant increase in efficiency, flexibility and process reliability. The “AGV vs. AMR” debate is becoming increasingly important – AGVs and AMRs differ in terms of their navigation technology and areas of application.

As specialists in conveyor technology components and intralogistics solutions with many years of experience, we offer sophisticated add-on products for AMR, AGV and other automated transport systems.

Our individually customizable add-ons expand existing AGV and AMR systems with, for example, buffers, transfer and feeding elements and height adjustments. Whether for automated production and logistics or automated conveyor technology – our solutions improve autonomous material transfer, support automated production and increase efficiency throughout the entire intralogistics process. Self-driving vehicles and autonomous robots can be seamlessly combined with existing intralogistics solutions and conveyor technology components with the help of our add-ons.

Our experts will be happy to advise you on the ideal addition to your AGV and AMR systems – optimize material flow, transfer and buffer zones in your business.

All add-on products can be individually adapted to your needs.

Below you will find an excerpt from our supplements for AMR and AGV.

Products

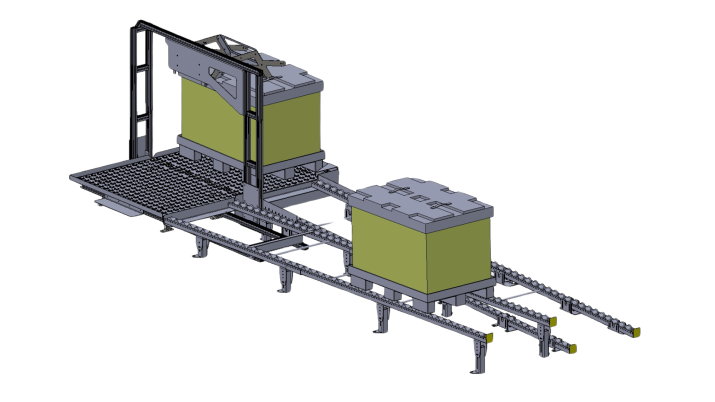

Pallet roller conveyor

Our two-lane pallet roller conveyor with integrated ball roller table and lid gripper is a clever buffer solution for pallets and boxes. It serves as intermediate storage within automated processes and enables autonomous material transfer to AMR and AGV systems. The potential of this addition to modern AGV transport systems is particularly evident in combination with plastic boxes.

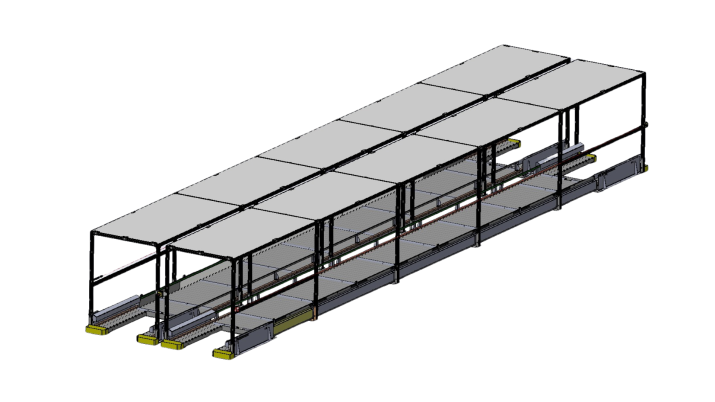

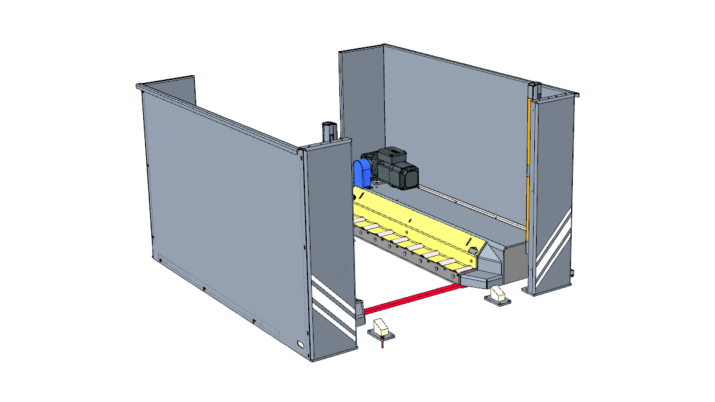

Driven storage track

The RBA50MR driven roller conveyor with a flat design is ideal for pallets, mesh boxes and containers. The integrated cover protects the conveyed goods from dust and dirt – perfect for use in smart warehouses and AMR logistics.

The transfer can be automated or manual using a pallet truck, allowing this module to be flexibly integrated into existing processes.

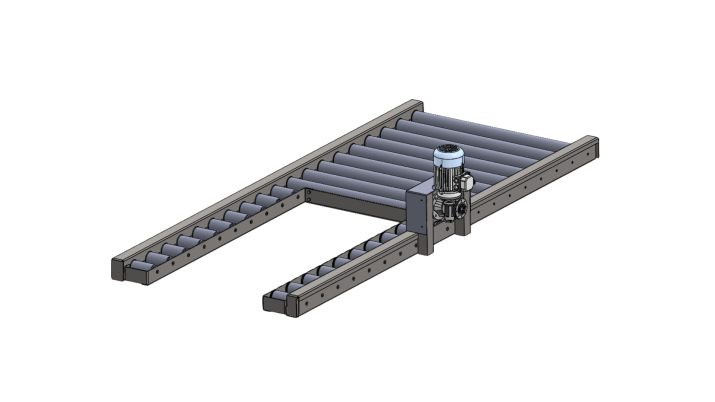

Driven loading element

This retrofittable loading element enables goods to be fed into existing systems from the front.

Ideal for AGV transport systems or AMR technology where a precise transfer of material is required.

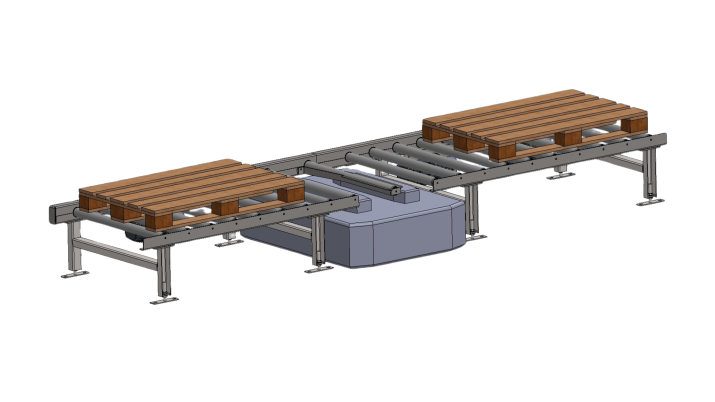

Driven loading element

This variant of a driven loading element is ideal for lateral transfer into your conveyor system.

It is particularly suitable for compact system layouts and can be easily integrated into existing Automated Guided Vehicle environments.

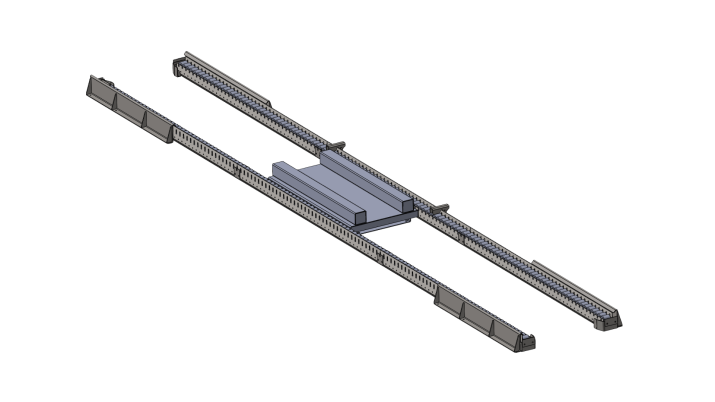

Gravity storage track

This non-driven roller conveyor operates as a buffer section for pallets and pallet cages – for example in front of a workstation. Pallets can be loaded flexibly from both sides.

A lifting table can optionally be integrated between the rails to enable ergonomic working – a perfect addition to any AMR production or automated warehousing system.

Hydraulic loading element

This compact retrofit module lifts a parked pallet and transfers it to the existing conveyor system via a powered roller conveyor. The solution is ideal for adding to automated environments, especially where space is limited or in combination with autonomous robots.

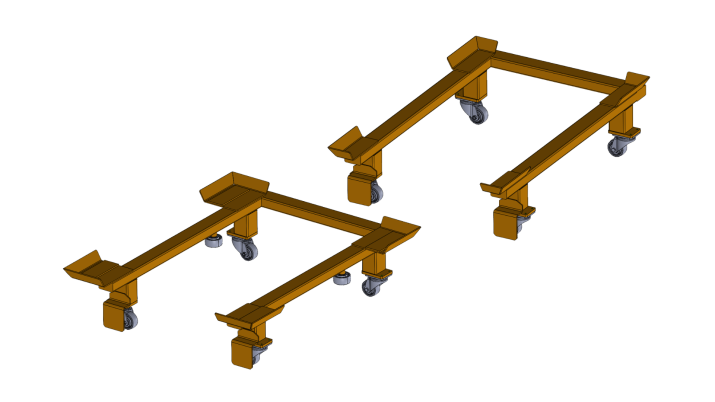

Various U-trolleys

Our U-trolleys are available in normal and tugger train-compatible versions and are compatible with 800 mm Euro pallets and 1000 mm industrial pallets. The trolley compatibility ensures efficient trolley management.

With a load capacity of 1000 kg, they can also be used to transport heavy loads in your company.

The pallets are placed on the U-trolley so that the employee can move them flexibly and create an ergonomic workstation – an ideal interface between manual tasks and AMR robots.

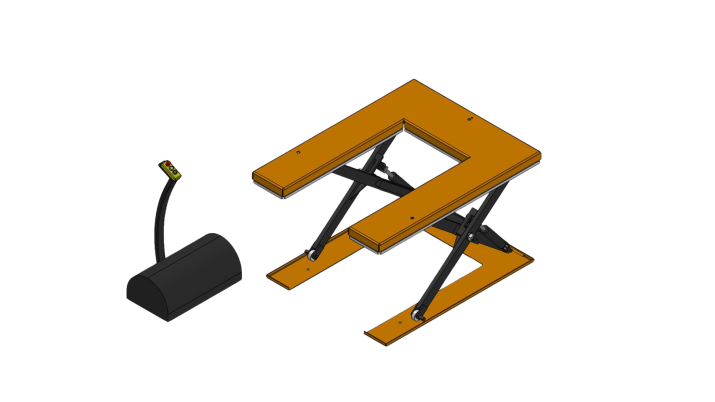

Lifting table HTCU

The U-shaped HTCU lifting table can be loaded with any pedestrian stacker, pallet truck or AGV or AMR system. With a load capacity of 1000 kg and an effective stroke of 775 mm, it offers an ergonomic solution for height adjustment in the material flow.

Variants with up to 1500 kg are also available – ideal for AGV pallet transport systems.

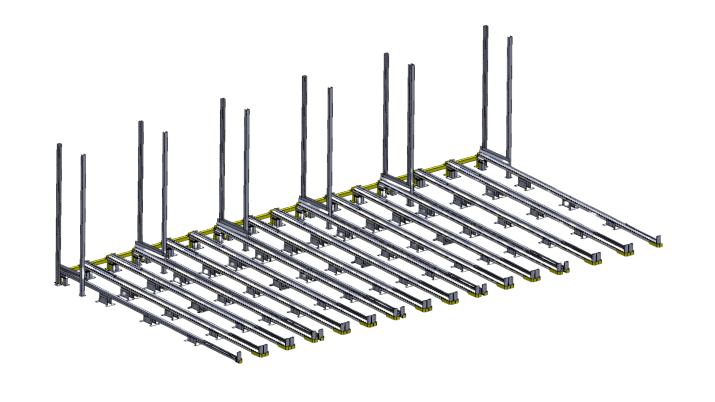

Pallet storage station

Our multi-lane pallet storage station with gravity roller conveyors is suitable as a space-saving storage solution under existing pallet racks.

As a buffer space, it optimizes the interaction between automated conveyor technology, self-propelled vehicles and manual order picking in logistics.