Light-duty applications

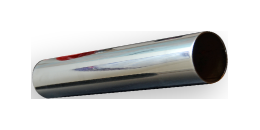

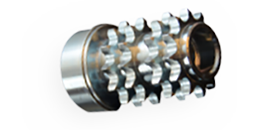

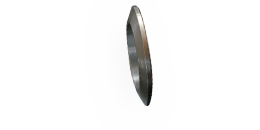

Conveyor rollers are a key component in many logistics solutions. KRAUS produces conveyor rollers for a wide range of applications and industries, such as logistics centres, package distributors, mechanical engineering companies or the food industry. Our product range includes steel, plastic and stainless steel conveyor rollers. Conveyor roller coating materials are just as diverse: From polished to chromed, phosphated, PU coated, knurled, cambered and flocked. In addition, we produce our rollers with a variety of sprockets or flanged wheels. You can design your conveyor rollers with the help of our configurator and then download the free CAD data.

Do you need special services? We would be happy to assist you!

Online Consulting

Improves surface quality

(and corrosion protection)

Prevents the carrier rollers from leaving marks on wood

Improves the sliding properties

of the axis material

(and corrosion protection)

Protects conveyed goods and reduces noise

We manufacture per your specifications

A wide range of features

(depending on the coating process)

Better wear-resistance

(thanks to hardened tooth flanks)

Better carry over to the conveyed material

(thanks to knurling)

Prevents the conveyor belt

from going off of its track

(on the input or output directions)

We manufacture per your specifications