- Conveyance of unit loads horizontally or at a slight upward gradient

- For continual material flow between machines and areas

Products

Roller conveyor RBA 50

Frame structure

Sheet steel profile (wall thickness 3 mm) with welded cross braces

Chain guard cover closed completely

Dimensions

Chain case: 120 x 60 x 3 mm

L-profile: 80 x 40 x 3 mm

Roller spacing: adapted depending on load

Conveyor rollers

Kraus conveyor rollers series 5020

Galvanised steel tube Ø 50 mm x 1.5 mm

Steel axle Ø 12 mm with internal thread M8x15, with double chain wheel, steel: 1/2" x 5/16", number of teeth = 14

Drive

Chain drive with three-phase gear motor 230/400 V – 50 Hz, IP55

The conveyor rollers are driven by a 1/2" x 5/16" chain from roller to roller Motor position: in the centre under the frame structure

Conveying speed: Standard speed 6–30 m/min

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 470 mm, 670 mm, 870 mm

Conveyor length: on request, depending on the roller spacing

Surface finish

Painted in RAL colours/galvanised

Advantages

Conveyance of unit loads horizontally or at a slight upward gradient

No downward gradient required

Sturdy design

Very good transmission of force

Safe to use thanks to chain guard cover

Low-noise running

Roller conveyor RBA 50 tangential

Frame structure

Sheet steel profile (wall thickness 3 mm) with welded cross braces

Chain guard cover closed completely

Dimensions

Chain case: 120 x 60 x 3 mm

L-profile: 80 x 40 x 3 mm

Roller spacing: adapted depending on load

Conveyor rollers

Kraus conveyor rollers series 5020

Galvanised steel tube Ø 50 mm x 1.5 mm

Steel axle Ø 12 mm with internal thread M8x15, with double chain wheel, steel: 1/2" x 5/16", number of teeth = 14

Drive

Chain drive with three-phase gear motor 230/400 V – 50 Hz, IP55

The conveyor rollers are driven by a 1/2" x 5/16" chain from roller to roller Motor position: in the centre under the frame structure

Conveying speed: Standard speed 6–30 m/min

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 470 mm, 670 mm, 870 mm

Conveyor length: on request, depending on the roller spacing

Surface finish

Painted in RAL colours/galvanised

Advantages

Conveyance of unit loads horizontally or at a slight upward gradient

No downward gradient required

Sturdy design

Very good transmission of force

Safe to use thanks to chain guard cover

Low-noise running

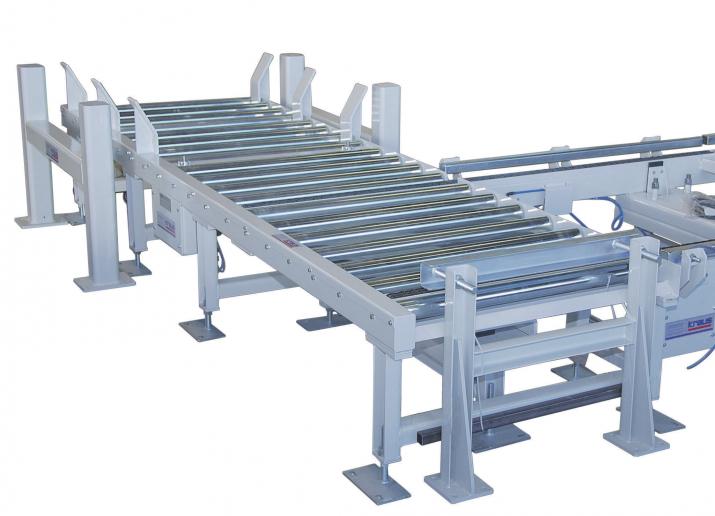

Roller conveyor RBA 80/89

Frame structure

Sheet steel profile (wall thickness 5 mm) with welded cross braces

Chain guard cover closed completely

Dimensions

Chain case: 150 x 70 x 5 mm

L-profile: 100 x 50 x 5 mm

Roller spacing: adapted depending on load

Conveyor rollers

Kraus conveyor rollers series 5105

Galvanised steel tube Ø 80 mm x 2 mm / Ø 89 mm x 3 mm

Steel axle Ø 20 mm with internal thread M10x20, with double chain wheel, steel: 5/8" x 3/8", number of teeth = 15

Drive

Chain drive with three-phase gear motor 230/400 V – 50 Hz, IP55

The conveyor rollers are driven by a 5/8" x 3/8" chain from roller to roller

Motor position: in the direction of transport, in the centre under the frame structure

Standard transport speed: 6–30 m/min

Conveyor width: the width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard belt widths: 985 mm, 1185 mm

Conveyor length: on request, depending on the roller spacing

Surface finish

Painted in RAL colours/galvanised

Advantages

Conveyance of pallets, skeleton containers, boards and barrels

Sturdy design

Very good transmission of force

Safe to use thanks to chain guard cover

Low-noise running

Conveyance of unit loads horizontally or at a slight upward gradient

Round belt conveyors

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 mm x 30 mm x 2 mm

Min. roller spacing: 25 mm

Conveyor rollers

Kraus conveyor rollers series 3760 (bead roller)

Galvanised steel tube Ø 50 mm x 1.5 mm

Steel axle Ø 12 mm with internal thread M8x15, with single or double bead

Drive

Drive with three-phase gear motor 230/400 V – 50 Hz, IP55

The conveyor rollers are driven by a vertical shaft underneath via round belts Ø 5 mm.

Motor position: in the centre under the frame structure

Standard transport speed: 6–24 m/min

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard conveyor widths: 470 mm, 670 mm, 870 mm

Standard conveyor lengths: 1000 mm, 2000 mm, 3000 mm

Design height

105 mm (bottom of side profile to top edge of conveyor roller, without chain guard cover, without drive unit)

Surface finish

Painted in RAL colours/galvanised

Advantages

Suitable for accumulation

Easy to combine

mit Standardrollenbahnen

sehr einfaches Funktionsprinzip

wartungs- und revisionsfrei

geräuscharmer Lauf

Accumulation roller conveyors

Frame structure

Sheet steel profile (wall thickness 3 mm) with welded cross braces

Chain guard cover closed completely

Dimensions

Chain case: 120 mm x 60 mm x 3 mm

L-profile: 80 mm x 40 mm x 3 mm

Roller spacing: adapted depending on load

Conveyor rollers

Kraus conveyor rollers series 5020 accumulation drive

Galvanised steel tube Ø 50 mm x 1.5 mm

Steel axle Ø 12 mm with internal thread M8x15, with double chain wheel, steel or PVC: 1/2" x 5/16", number of teeth = 14

Drive

Chain drive with three-phase gear motor 230/400 V – 50 Hz

The conveyor rollers are driven by a 1/2" x 5/16" chain from roller to roller.

The force is transmitted to the tube by means of the slip coupling.

Motor position: in the centre under the frame structure

Standard transport speed: 6-24 m/min

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 470 mm, 670 mm, 870 mm

Standard conveyor lengths: 1905 mm, 3048 mm, 3810 mm, 4953 mm, 5715 mm

Surface finish

Painted in RAL colours/galvanised

Advantages

Transport without accumulation pressure

Sturdy design

Safe to use thanks to chain guard cover

Low-noise running

Mini tapered conveyor roller curves, power-driven

Frame structure

Frame comprising of rolled-up flat steel with welded cross-bars

Frame height 70 mm

Wall thickness 3 mm

Conveyor rollers

Kraus conveyor rollers series 0600

Steel tube Ø 20 mm x 1.5 mm with plastic tapered elements slid in place, with double chain wheel, steel 6 x 2.8 mm, number of teeth = 17, Steel axle Ø 8 mm with internal thread M5

Drive

Chain drive from roller to roller

Three-phase gear motor 230/400 V – 50 Hz, IP55

Motor position: in the direction of transport, in the centre under the frame structure

Standard conveyor widths

240 mm, 340 mm, 440 mm, 540 mm

Inner radius

360 mm

Surface finish

Painted in RAL colours/galvanised

Advantages

Extremely versatile

Quiet, safe to use and low-maintenance

Simple assembly

Precise curve guidance and high degree of working safety

Tapered conveyor roller curves, power-driven

Frame structure

Frame comprising rolled-up flat steel with welded cross-bars

Frame height 100 mm

Wall thickness 3 mm

Conveyor rollers

Kraus conveyor rollers series 3700

Steel tube Ø 50 mm x 1.5 mm with plastic tapered elements slid in place, with double chain wheel, steel 1/2" x 5/16", number of teeth = 14

Steel axle Ø 14 mm with internal thread M10

Drive

Chain drive from roller to roller

Three-phase gear motor 230/400 V – 50 Hz, IP55

Motor position: in the direction of transport, in the centre under the frame structure

Standard conveyor widths

470 mm, 670 mm, 870 mm, 1070 mm

Inner radius

900 mm

Surface finish

Painted in RAL colours/galvanised

Advantages

Extremely versatile

Quiet, safe to use and low-maintenance

Simple assembly

Precise curve guidance and high degree of working safety

Accordion roller conveyors, power-driven

Frame structure

Accordion connection galvanised steel with stabilizers

Conveyor width

Conveyor widths: 400 mm, 500 mm, 600 mm

Conveyor length

maximum extended length achievable: 7,500 mm

Height adjustment: stepless from 720 to 1,150 mm

Drive

Round belt drive from roller to roller

Small motors 24V

Motor position: in the direction of transport, in the centre under the frame structure

Incl. reversing switch for reverse operation

Advantages

Versatile use: for constantly changing locations and variable conveyor routes, as buffer or run-out track

Simple extension to a conveyor with manual and gravity drive

Curve designs of 180° possible

Low space requirement

Our customers