- All-purpose conveyance solution for the conveyance of unit loads

- for continual material flow between machines and areas

Products

Mini module conveyor belt with motor-driven roller

Frame structure

Special profile structure with bolted cross braces

Conveyor belt

Module belt, grey (PP, FTA-suitable)

Belt width: depending on application case and material to be conveyed

Standard widths

from 150 mm in 50 mm steps

Standard length

On request from 250 mm axle spacing

Drive

KRAUS motor-driven roller 24V, IP54

Reversal on both sides: Diameter 34 mm

Drive position centre with 78.8 mm diameter

Conveying speed: 3, 6, 9, 12, 15, 18, 24, 36 m/min

Surface finish

Anodised aluminium, zinc plated steel components

Advantages

Compact design as individual or connecting element

High flexibility

Maximum efficiency thanks to KRAUS motor-driven roller

Conveyor belt FB 50 ALU

Frame structure

Aluminium system profile, anodised, with bolted cross braces

Frame dimensions: 50 x 50 mm

Conveyor belt

Standard PVC smooth, black

Belt width: depending on application case and material to be conveyed

Standard conveyor lengths

1000 mm, 2000 mm, 3000 mm, 4000 mm, 5000 mm

Drive

Three-phase gear motor 230/400 V – 50 Hz, IP55

Drum diameter: 55 mm

Standard drive position: on the right-hand side seen in direction of conveyance, directly attached to the drive wheel

Conveying speed: 6-30 m/min

Surface finish

Anodised aluminium, zinc plated steel components

Advantages

Safe and gentle conveyance of sensitive goods

Optimum adaptation possibility of belt version

Can be combined with any of our accessories

Conveyor belt FB 80 ALU

Frame structure

Aluminium system profile, anodised, with bolted cross braces

Frame dimensions: 80 mm x 40 mm

Conveyor belt

Standard PVC smooth, black

Belt width: depending on application case and material to be conveyed

Standard conveyor lengths

2000 mm, 4000 mm, 6000 mm, 8000 mm, 10,000 mm

Drive

Three-phase gear motor 230/400 V – 50 Hz, IP55

Drum diameter: 90 mm

Standard drive position: on the right-hand side seen in direction of conveyance, directly attached to the drive wheel or chain drive

Conveying speed: 3–36 m/min

Surface finish

Anodised aluminium, zinc plated steel components

Advantages

Safe and gentle conveyance of sensitive goods

Optimum adaptation possibility of belt version

Can be combined with any of our accessories

Combines the lightweight design of the FB50 with higher load capacity

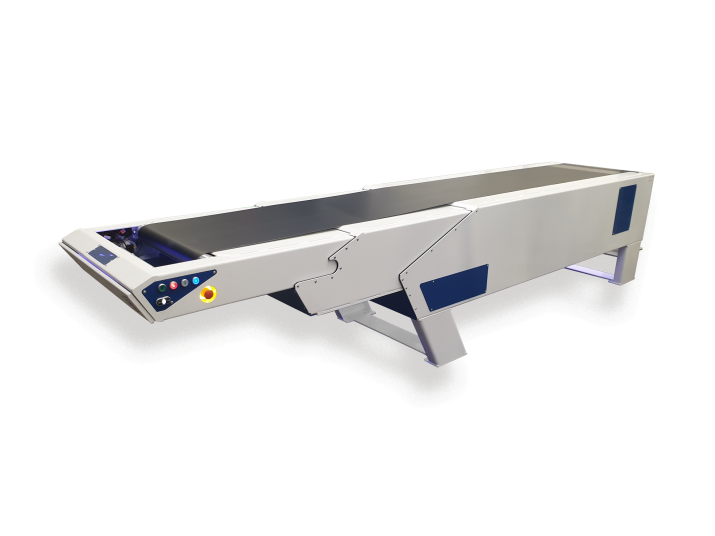

Conveyor belt FB 90 STEEL

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Conveyor belt

Standard PVC smooth, black

Belt width: depending on application case and material to be conveyed

Standard conveyor lengths

2000 mm, 4000 mm, 6000 mm, 8000 mm, 10,000 mm

Drive

Three-phase gear motor 230/400 V – 50 Hz, IP55

Drum diameter: 90 mm

Standard drive position: on the right-hand side seen in direction of conveyance, directly attached to the drive wheel or chain drive

Conveying speed: 6–30 m/min

Surface finish

Painted in RAL colours/galvanised

Advantages

Safe and gentle conveyance of sensitive goods, even if these have a higher weight

Optimum adaptation possibility of belt version

Can be combined with any of our accessories

Conveyor belt FB 150 STEEL

Frame structure

Steel plate (5 mm), canted, with bolted cross braces

Conveyor belt

Standard PVC smooth, black

Belt width: depending on application case and material to be conveyed

Conveyor length

on request

Drive

Three-phase gear motor 230/400 V – 50 Hz, IP55

Drum diameter: 150 mm

Standard drive position: on the right-hand side seen in direction of conveyance, directly attached to the drive wheel or chain drive

Conveying speed: on request

Surface finish

Painted in RAL colours/galvanised

Advantages

Use with high weight load

Optimum adaptation possibility of belt version

Can be combined with any of our accessories

Module belt conveyor FB50

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Conveyor belt

Module belt, grey

Belt width: depending on application case and material to be conveyed

Standard conveyor lengths

1000 mm, 2000 mm, 3000 mm, 4000 mm, 5000 mm

Drive

Three-phase gear motor 230/400 V – 50 Hz, IP55

Drum diameter: 50 mm

Standard drive position: on the right-hand side seen in direction of conveyance, directly attached to the drive wheel or chain drive

Conveying speed: 3-36 m/min

Surface finish

Painted in RAL colours/galvanised

Advantages

Simple maintenance

Highly flexible width : length ratio

Belt surface easy to clean

Form-locking drive element

Can be combined with any of our accessories

Module belt conveyor FB90

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Conveyor belt

Module belt, grey

Belt width: depending on application case and material to be conveyed

Standard conveyor lengths

1000 mm, 2000 mm, 3000 mm, 4000 mm, 5000 mm

Drive

Three-phase gear motor 230/400 V – 50 Hz, IP55

Drum diameter: 90 mm

Standard drive position: on the right-hand side seen in direction of conveyance, directly attached to the drive wheel or chain drive

Conveying speed: 3–36 m/min

Surface finish

Painted in RAL colours/galvanised

Advantages

Simple maintenance

Highly flexible width : length ratio

Belt surface easy to clean

Form-locking drive element

Can be combined with any of our accessories

Angled belt conveyors

Version

Angled belt conveyors permit stepless, uninterrupted transitions with horizontal inflow and/or discharge zones.

These horizontal conveyor belt zones guarantee smooth transition of the products to the conveyor belt or from the conveyor belt to further Systems.

An angled belt conveyor version is possible for all conveyor belt types (FB 50 ALU, FB 80 ALU, FB 90 and FB 150).

Advantages

Very good pick-up or discharge of the conveyed products

Stepless, uninterrupted transition in the angled area

Can be made of aluminium, galvanised/coated steel or stainless steel

Sturdy design, so no twisting , leading to greater belt running accuracy

Can be combined with any of our accessories

Hinged belt conveyor

Frame structure

Basis FB 80

Aluminium system profile, anodised, with bolted cross braces

Frame dimensions: 80 x 40 mm

Basis FB 90

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Hinged belt

Standard module belt

Hinged belt width

The width depends on the respective application case and the unit loads to be conveyed.

Standard conveyor lengths

2000 mm, 4000 mm, 6000 mm

Drive

Three-phase gear motor 230/400 V – 50 Hz

Standard drive position: on the right-hand side seen in direction of conveyance

Conveying speed: 3-36 m/min

Surface finish

Zinc plated steel, anodised aluminium

Advantages

Material resistant to rotting

Durable

Physiologically safe

Problem-free cleaning

Form-locking drive element

Belt curves

Specifications

Conveying angle

30°, 45°, 60° and 90°

Nominal radius

1.900 mm and 2.600 mm

Nominal width

450 mm until 1.050 mm

Conveying height

min. 350 mm

Conveying speed

max. 1,2 m/s

Load capacity

50 kg/lfm

Accessories

Supports, Corvers

Options

Customized dimensions, e.g. angels, radii or width

Side guards

Adjustable conveying speed

Reversing operation

Sensors, e.g. for flow monitoring

Without support or with ceiling suspension

Flexible use

The frame of the belt curves consists of stable, torsion-free aluminium profiles. The combined drive and tensioning unit ensure low-noise-operation. Coated drive pulleys and tapered conveyor pulleys are used for optimum power transmission. The belt drive works based on friction locking and is capable on conveying piece weights up to 50 kg/m.

Ergonomic

The possibility of delivering belt curves with individual conveyor angles guarantees a high degree of flexibility. Plug-on motors are used as drives, with the drive position located on the inside or outside of the pulley, depending on the conditions. This compact and lightweight design allows easy integration into existing systems. In addition, it is possible to manufacture belt curves with individual conveying angles. These are suitable for continuous operation and are virtually maintenance-free.

Conveyor belt

An antistatic belt with two fabric layers is used as standard, optionally available with smooth or structured carrying side. On request, the belt conveyor can also be supplied with a food-safe or flame-retardant belt.

Belt adjustment

All moving parts are enclosed or, like the lower run, covered with perforated sheet metal. Fine adjustment is nevertheless possible without removing protective plates.

Side guards

These are available in various heights and can be easily and seamlessly added to guards on existing conveyor system.

Telescopic Belt Conveyor (CompactLoader)

Specifications

Belt width

600 / 800 / 1.000 mm

Basic lengths

3.000 - 7.500 mm (3 stages)

5.000 - 7.500 mm (4 stages)

Extended lengths

6.000 - 18.500 mm (3 stages)

14.300 - 22.800 mm (4 stages)

Conveying height

min. 800 mm

Conveying speed

0,5 m/s

Conveying direction

Loading and unloading

Load capacity

50 kg/m

Accessories

Ball castors / roller beds at infeed

Lighting in front segment

Options

Light sensor at infeed and / or outfeed

Hydraulic height adjustment

Mobile movable on rails

Control connection to existing conveyor system

Adjustable conveying speed

Without support or with ceiling suspension

Controls in front and sides

Physical relief

The use of telescopic conveyors supports and at the same time reduces the physical strain.

Performance increase

Performance in loading and unloading operations is significantly increased due to higher process optimization and improvement of material flow.

Profitability

Cargo is transported directly (without intermediate storage). Furthermore, telescopic conveyors can be used quickly.

Flexibility

The same telescope can be used on multiple gates, with rail systems to move the telescopes between loading and unloading positions. With a hydraulic height adjustment (optionally available), the telescope can be adjusted in inclination to adjust the transfer point in height.

Reliability

The robust welded construction, various reinforcements and the drive concept ensure a long service life.

Safety

The telescopic conveyors fullfill all safety guidelines, such as an emergency retraction function.

SmartLoader

Specifications

Telescope

1.065 mm retracted / 2.030 mm extended (driven)

Tilting

+/- 17° lifting and lowering (driven)

Belt drive

Reversible

Belt

Width 500 mm (longitudinally grooved)

Dimensions L x D x H

1.065 mm x 1.140 mm x 800 mm

Options

Longer extended length of approx. 3.0 m

Adjustable conveying speed

Connection to the field bus system

Integration in material handling system

Movable on rails

Ergonomic

The SmartLoader closes the gap between conveyor and container or trailer with telescopic belt.

Mobility

The SmartLoader can be quickly and easily positioned either on castors or rails and handle a variety of loading and unloading situations.

Compact design

The telescopic conveyor has a compact design with a retracted length of 1,065 mm (up to approx. 2,030 mm when extended) and is used for loading baggage, loose unit loads and flexible shipments.

Integration

The Smartloader is ideally suited for integration into e.g. a belt conveyor or in combination with driven extendable roller conveyors as an alternative to telescopic conveyors.

Flexibility

The maximum extension length is achieved by means of 2 extension stages. In combination with a lifting-lowering range of approx. 17° and reversing operation, almost all loading and unloading stages, such as e.g. loading positions in containers can be reached. Depending on the connection, positioning is manual and flexible.

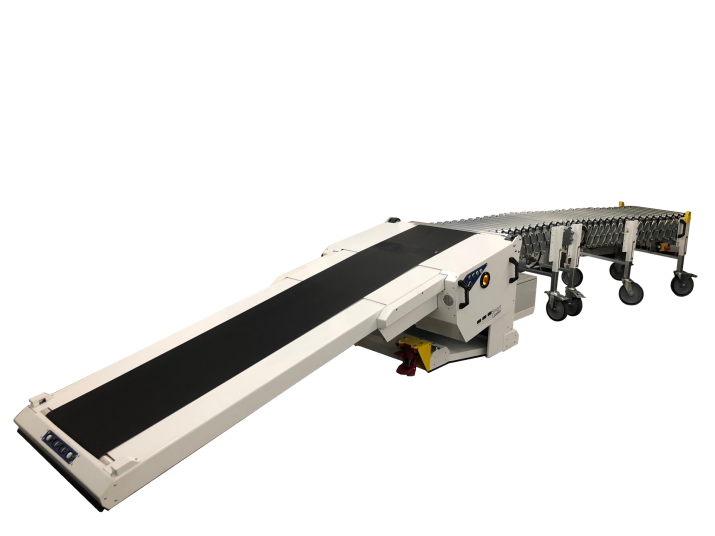

GroundLoader

Specifications

Belt width

600 mm

Conveying height

800 mm - 2.000 mm

Conveying speed

0,5 m/s

Load capacity

50 kg/m

Options

Extendable roller conveyor are also available as gravity conveyors

Adjustable conveying speed

Mechanical stop

Reversable conveying direction

Sensor technology, e.g. for automatic stop

Coupling to existing conveyor equipment

Hydraulic motor-driven

Application

The GroundLoader is used to bridge structural conditions, e.g. if no loading ramp is available or a truck has to be loaded and unloaded at ground level.

Construction

The GroundLoader consists of a movable frame on which a belt conveyor and a driven extendable roller conveyor are mounted on an cantilever. The belt conveyor can be hydraulically adjusted to the height of the truck. The extendable roller conveyor is extended to the appropriate loading or unloading position.

Mobility

The large diameter of the castor wheels mounted on the chassis makes it easy to move, even on uneven ground.

Connection to conveyor technology

The addition of a further extendable roller conveyor, e.g. to convey unit loads into a warehouse, is also a common solution.

Accessories

A mobile loading and unloading platform is available on customer request.

Adjustability

The alignment of the extendable roller conveyor parallel to the loading area can be easily adjusted.