Logistical solutions provided by our in-house production teamWe provide solutions for your specific needs.Take advantage of our know-how by using the services of our qualified technicians.Customised conveyor rollers, lift tables, special customised designs of heavy duty trailers - we offer a wide range of logistical solutions.Here are a few examples of our logistical solutions. |

Projects

Fully automatic conveyance of washing baskets through a washer system

Project describtion

Fully automatic conveyance of washing baskets through a washer system in the night shift. Transport without accumulation pressure thanks to one motor-driven roller per washing basket. A total of 47 motor-driven rollers were installed.

Advantages

Transport without accumulation pressure, first project with logistics function

No PLC required

Stepless speed regulation

Pallet undercarriages, zinc plated

Use

The carriages are used for transporting containers of dirty washing.

Properties

The galvanised surface makes it easy to clean.

Load capacity of 1000 kg.

Customer-specific solutions possible on request.

Transport cart for transporting automotive parts

Properties

The plastic compartments protect the painted parts from scratches

The base frame measures approx. 1200 x 800 mm

This transport cart is suitable or use with a tugger train.

Customised versions can be implemented.

Transport cart with plastic compartments

Use

Transport cart with plastic compartments for the transport of radiators.

Properties

The plastic compartments prevent the sensitive components becoming damaged or scratched.

The dimensions of the compartments and the cart were manufactured to customer requirement.

Transport device for sensitive components

Requirement

Transport device for sensitive components.

Properties

Transport cart with plastic compartments.

This model was manufactured with a metal base on customer wishes. The metal base increases the sliding ability of the plastic boxes and thus supports fast unloading.

The transport cart is easy to move.

Integration of a lift table in conveying equipment

Requirement

Lift table integration in a conveyor for adaptation of the conveyor height to working height.

Version

Sacks are palletised on the tables, which means the lift table works at 40 cycles per hour in 2-shift operation.

Properties

Plat form size 1.6 x 1.5 m

Load capacity 2t

Double scissors with effective stroke 1.8 m

Lift table for an optimum, ergonomic workstation

Requirement

Lift tables with individual working height adjustment to accommodate every employee.

Version

The lift table has very sturdy dimensions. When the lift table is retracted, it may be driven over by truck and other heavy equipment (bridge class I ÖNORM B4002 60t).

Properties

Platform size 2 x 1.2 m

Load capacity 4t

Effective stroke 1.1 m

Lift table for stage design

Requirement

Lift table is used to overcome an on-site step.

Version

Secured by electrically queried plug-in railings, PVC blind,

Properties

Platform size 7800 x 1000 m

Load capacity 500 kg

Tandem scissors

Lift table installation in a concrete pit in the road

Requirement

Lift table installation in the road for easy loading and unloading of bulky goods onto and from trucks.

Version

The lift table was integrated in a concrete pit in the road. Since the lift table is located in the access road for the fire service, it had to be equipped with an emergency lowering device. All safety-related equipment such as railings, PVC blind, switch rails and much more are included. The unit is housed protected in the building.

Properties

Platform size 5 x 2.4 m

Load capacity 6 t

Effective stroke 1.6 m

Lift table for overcoming an on-site step

Requirement

Lift table for overcoming an on-site step 1.8 m in height.

Version

The lift table is completely hot galvanised and suitable for outdoor use. It has all the safety-related technical applications such as locked doors, railings, PVC blind, switch rails.

The unit is executed protected in the building.

Properties

Load capacity: 1000 kg,

Platform size: 2800 x 2000 mm

Lift table replacement

Requirement

Replacement of an old, rusty lift table by a galvanised model from KRAUS.

Version

The lift table has very sturdy dimensions. When the lift table is retracted, it may be driven over by truck and other heavy equipment (bridge class I ÖNORM B4002 60t).

Use

Trucks to be inspected drive over the lift table and then stop. The loaded goods are moved from the truck onto the lift table for inspection. Then the inside of the truck can be inspected.

Properties

Platform size 5 x 3 m

Effective stroke 1.6 m

Stroke load capacity 10 t

KRAUS Hubtisch Video - Projekte

Pallet supplies to a robot cell for commissioning Euro boxes in a high-bay warehouse

Project description

Pallet supplies (Euro pallets weighing max. 150 kg) to a robot cell for commissioning Euro boxes in a high-bay warehouse. Use of MRI60 motor-driven rollers especially designed for the restricted space conditions for the return conveyor section on the 2nd level.

Avantages

Pallet conveyor (max. 150 kg) with 48V

No frequency converter required

Adaptation of our conveying elements to on-site conditions

Properties

One example of the flexible adaptation of our conveying elements to on-site conditions at our customers is the mini tapered idler roller curve shown with 2x 90° and gradient, in the form of a helix, as well as straight sections between the curves and as a transfer section to the downstream conveyor belt.

Requirement

The packages from the foiling machine have to be transported between an existing staircase outside the hall into the neighbouring hall and overcome a height difference of 1,000 mm.

The equipment was put into operation exactly on schedule thanks to the exact coordination between all those involved in the projects.

Customer/branch: food industry

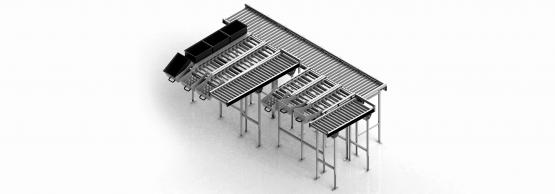

Flat pallet supply roller conveyor in tandem design

Project description

A flat pallet supply roller conveyor in tandem design for extra-long manual pallet trucks with 2 Euro pallets was realised for an equipment manufacturer.

The specification was to supply Euro pallets to a roller conveyor by pallet truck. The design height was reduced to 80 mm. The customer integrated the drive in the lift table pit to prevent it projecting above the roller conveyor.

Customer/branch: Equipment manufacturer

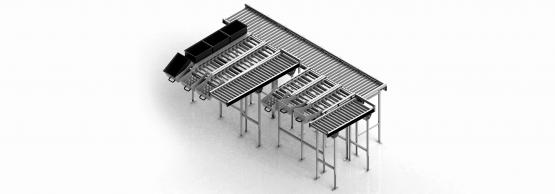

Roller conveyor in restricted space with large range of parts

Project description

The restricted space situation and the large range of parts were the reason we realised a multi-track, double-decker roller conveyor with accumulation mode and extremely tight roller pitch (from 31 mm). It is based on the KRAUS RBA50 roller conveyor which has been specially adapted. A suitable sub-structure and the required control functions were part of the scope of supply. Our customer has been using it successfully for years for the production of larger gearboxes for tractors and trucks.

Customer/branch: Mechanical engineers, automotive suppliers

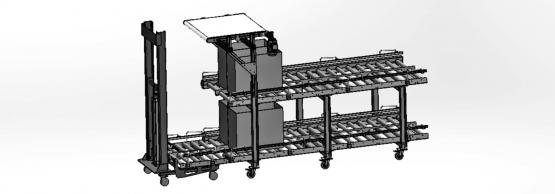

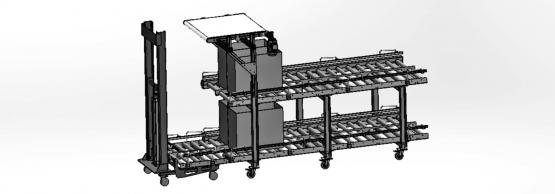

Conveying eqipment for fast supply of an assembly line

Project describtion

The conveyor system built by KRAUS is used for the fast and simple supply of an assembly line.

The main focus was on the ergonomic and safe provision of parts using metal boxes.

The swivel mechanism for the first box has been designed in such a way that the full box swivels gently downwards and only reaches the initial position again when

Customer/branch: Mechanical engineering, automation

Roller conveyor with lifter

Project describtion

Pick-up of buffered empty cardboard boxes of different sizes by a lifter.

The boxes on the lifter are filled with injection-moulded parts of different sizes and deposited on the upper conveyor section after a customised filling duration (can take between hours and days).

Advantages

Lower weight of the roller conveyor

Optimum utilisation of space at the lifter

Power-driven transfer element

Project description

Serves as a power-driven transfer element between two conveyor belts for small bags with food. The restricted space conditions make a compact drive necessary. In the case of the motor-driven roller it is directly integrated in the conveying element, the idler roller.

Advantages

No constraining contour

Simple set-up

Stainless steel version

Discharge belt for nOK parts

Project description

Discharge belt for nOK parts. These belts are located on a weighing unit, selection is made on the basis of weight.

Advantages

No constraining contour

Simple set-up

Stainless steel version

Our customers