- Conveyance of unit loads horizontally by hand or with gravity drive up to 5% gradient

- Load capacity range: from 15 to 2,500 kg depending on version

- For versatile use

- Modular design permits precise adaptation to the task on hand

- Straightforward attachment of additional equipment

- Easy and quick extension

- Simple changeover between manual and gravity drive

- Simple assembly

- Low-maintenance, wear-free

- Tested quality rollers from in-house production

Projects

Conveying eqipment for fast supply of an assembly line

Project describtion

The conveyor system built by KRAUS is used for the fast and simple supply of an assembly line.

The main focus was on the ergonomic and safe provision of parts using metal boxes.

The swivel mechanism for the first box has been designed in such a way that the full box swivels gently downwards and only reaches the initial position again when

Customer/branch: Mechanical engineering, automation

Adaptation of our conveying elements to on-site conditions

Properties

One example of the flexible adaptation of our conveying elements to on-site conditions at our customers is the mini tapered idler roller curve shown with 2x 90° and gradient, in the form of a helix, as well as straight sections between the curves and as a transfer section to the downstream conveyor belt.

Requirement

The packages from the foiling machine have to be transported between an existing staircase outside the hall into the neighbouring hall and overcome a height difference of 1,000 mm.

The equipment was put into operation exactly on schedule thanks to the exact coordination between all those involved in the projects.

Customer/branch: food industry

Products

MINI roller conveyors

Conveyor rollers

Kraus conveyor rollers series 500 (PVC)

Plastic tube Ø 20 mm x 1.5 mm axial spring-loaded steel axle Ø 6 mm

Conveyor roller bearing: Plastic housing with steel ball bearing

Frame structure

Steel L-profile, galvanised or powder-coated, with bolted cross braces

Frame dimensions: 70 x 30 x 3 mm

Min. roller spacing: 25 mm

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 230 mm, 330 mm, 430 mm

Standard conveyor lengths: 1000 mm, 2000 mm, 3000 mm

Surface finish

Painted in RAL colours/galvanised

Advantages

Extremely versatile

Quiet, safe to use and low-maintenance

Simple assembly

Mini tapered conveyor roller curves

Frame structure

Frame comprising rolled-up flat steel with welded cross-bars

Frame height 70 mm

Wall thickness 3 mm

Conveyor rollers

Kraus conveyor rollers series 500

Steel tube Ø 20 mm x 1.5 mm with plastic tapered elements slid in place

Steel axle Ø 8 mm with internal thread M5

Standard conveyor widths: 230 mm, 330 mm, 430 mm, 530 mm

Design height

75 mm

Inner radius

360 mm

Surface finish

Painted in RAL colours/galvanised

Advantages

Extremely versatile

Small radius for more flexibility

Quiet, safe to use and low-maintenance

Simple assembly

LIGHT-DUTY roller conveyors

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Min. roller spacing: 75 mm

Conveyor rollers

Kraus conveyor rollers series 1000 (PVC)

Plastic tube Ø 50 mm x 2.8 mm axial spring-loaded steel axle Ø 10 mm

Conveyor roller bearing: Plastic housing with steel ball bearing

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 320 mm, 470 mm, 620 mm

Standard conveyor lengths: 1000 mm, 2000 mm, 3000 mm

Surface finish

Zinc plated

Advantages

Extremely versatile

Gentle conveyance thanks to plastic rollers

Simple lateral guidance by fitting the conveyor rollers in the central row of holes without extra charge

Simple assembly

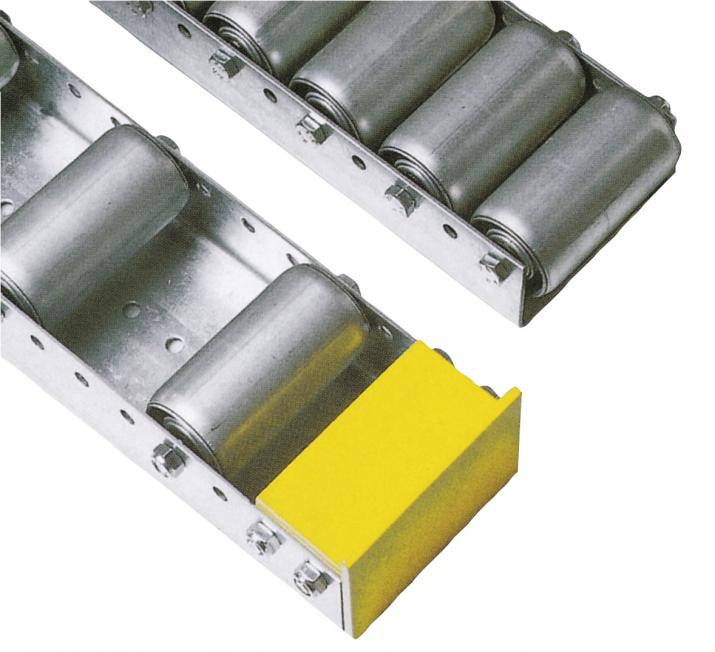

STANDARD roller conveyors

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Min. roller spacing: 75 mm

Conveyor rollers

Kraus conveyor rollers series 3700

Galvanised steel tube Ø 50 mm x 1.5 mm

Axial spring-loaded steel axle Ø 10 mm

Conveyor roller bearing: Plastic housing with precision bearing

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 320 mm, 470 mm, 620 mm

Standard conveyor lengths: 1000 mm, 2000 mm, 3000 mm

Surface finish

Zinc plated

Advantages

Extremely versatile

Simple lateral guidance by fitting the conveyor rollers in the central row of holes without extra charge

Simple assembly

Roller conveyor curves

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Roller spacing: 75 mm (inner)

Conveyor rollers

Kraus conveyor roller series 3700 (steel) or series 1000 (PVC)

Series 3700: Galvanised steel tube Ø 50 mm x 1.5 mm axial spring-loaded steel axle Ø 10 mm

Conveyor roller bearing: Plastic housing with precision bearing

Series 1000: Plastic tube Ø 50 mm x 2.8 mm, axial spring-loaded steel axle Ø 10 mm

Conveyor roller bearing: Plastic housing with steel ball bearing

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 320 mm, 470 mm, 620 mm

Surface finish

Zinc plated

Advantages

Cost-saving thanks to divided standard rollers (2 rollers on one axle)

Version as light-duty or standard roller conveyor or combined

Version in stainless steel for the food industry

Various curve radii can be set up, standardised appearance thanks to standardised rollers or bearing plates

Tapered conveyor roller curves

Frame structure

Steel C-profile, galvanised, with bolted cross braces

Frame dimensions: 100 x 30 x 2 mm

Roller spacing: 75 mm (inner)

Conveyor rollers

Kraus conveyor rollers series 6000

Steel tube Ø 50 mm x 1.5 mm with plastic tapered elements slid in place

Steel axle Ø 14 mm with internal thread M10

Standard conveyor widths

470 mm, 670 mm, 870 mm, 1070 mm

Design height

105 mm

Inner radius

860 mm

Surface finish

Zinc plated

Advantages

Optimum use of room space

Quiet and low-maintenance

Simple assembly

Pallet roller conveyors

Frame structure

Steel L-profile galvanised or powder-coated, with bolted cross braces

Frame dimensions: 80 x 40 x 5 mm

Min. roller spacing: 100 mm

Conveyor rollers

Kraus conveyor rollers series 2600

Galvanised steel tube Ø 89 mm x 3 mm or Ø 80 mm x 2 mm

Steel axle Ø 10 mm with internal thread M10

Conveyor roller bearing: Steel housing with steel ball bearing

Conveyor width

The width is determined by the properties and weight of the unit load – the unit load should be resting on at least 3 rollers

Standard widths: 920 mm, 1120 mm

Standard conveyor lengths: 1000 mm, 2000 mm, 3000 mm

Surface finish

Painted in RAL colours/galvanised

Advantages

Conveyance of pallets, skeleton containers, boards and barrels

Sturdy design

Low-noise running

Conveyance of unit loads horizontally or at a slight downwards gradient

Pallet roller rails / pallet roller conveyor rails

Version

The profile is fitted with rollers/skate wheels in certain spacings.

A row of holes on the rail base is used for fastening the rail to the sub-structure or the floor.

Use of pallet roller rails

Flow racks and flow stores

Longitudinal and lateral conveyance of pallets

or if a roller conveyor with rollers throughout cannot be used

Use of pallet roller conveyor rails

Pallet roller conveyor rails are used if a roller conveyor with rollers throughout cannot be used and the low-cost pallet roller rail is too narrow

Can also be used

As a two- or three-section roller conveyor

In place of pallet roller conveyors for flow racks

Advantages

Cost-saving

Can easily be integrated in existing systems

Space-saving use

Optimum adaptation to the load capacity actually required

Sturdy design

Can be loaded by pallet truck

Accordion skate wheel and roller conveyors

Frame structure

Accordion connection galvanised steel with stabilizers

Conveyor width

Standard widths: 300 mm, 400 mm, 500 mm

Conveyor widths up to 1200 mm on request

Conveyor length

maximum extended length achievable: 8000 mm

Height adjustment: stepless from 720 to 1150 mm

Skate wheels

Conveyor skate wheels made of plastic or steel

Ball bearing mounted Ø 48 mm

Steel axle Ø 8 mm

Skate wheel spacing: depending on extended length stepless from 32 to 130 mm

Advantages

Versatile use: for constantly changing locations and variable conveyor routes, as buffer or run-out track

Simple changeover from manual to gravity drive

Curve designs of 180° possible

Low space requirement